The Directorate General of Shipping, Mumbai has issued a casualty circular into the death on board a tanker while undergoing repairs at berth, leading to a tanker explosion.

The circular highlights an incident on Indian-registered tanker M T Patriot that resulted in the loss of one life and injuries to three shore-contracted personnel on board.

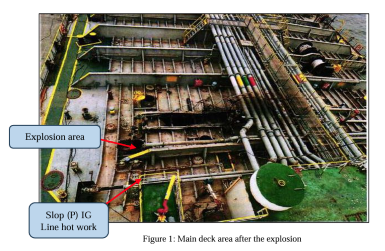

The casualties occurred due to an tanker explosion inside the port-side Slop tank while cutting of nuts and bolts, using hot work, was being carried out on the Inert Gas line at the main deck.

The tanker was undergoing repairs that included renewal of sections of the Inert Gas (IG) pipeline on main deck at the Port of Chennai at repair berth since 30th October 2023 after taking the necessary permissions from Port authorities and PESO. Repairs were on going on the boiler and hence additional repairs were planned on the deck area by the onsite team.

On 10 November 2023 at 00.05 there was an explosion followed by fire on the tanker while the repairs were being carried out near the vicinity of Slop tank (port) which led to the fatality of one shore personnel and injuries to three others from the shore team.

The vessel’s tank dome and the internals of the Cargo Oil Tank No.7 (port) and Slop tank (port) were damaged and the main deck plating between Frame No. 49-50 were badly ruptured.

Why it happened:

• The vessel was sufficiently manned, held all required valid statutory certificates, and encountered moderate, cloudy, and occasionally rainy weather during the incident.

• Gas freeing was not carried out as per industry standards as per ISGOTT due to nonavailability of IG system for purging since boiler was not operational.

• All other cargo tanks were gas-freed before the vessel came to the repair port after discharging the cargo at Paradip. The tank washings were collected in the slop tank, which were later discharged ashore at the Port of Chennai. The cargo tanks were thereafter gasfreed by the introduction of fresh air in fresh air mode by IG blowers and the HC was brought below 1% Lower Explosive Limit (LEL).

• Due to non-availability of inert gas on board at berth, the tank cleaning & gas freeing operations of Slop P tank were carried out after checking that tank atmosphere was having HC less than 2% by Volume. As the vessel did not have inert gas, the only condition applicable in this instance would be (‘Non-Inerted ships’)5 and vessel was required to take precautions thereof. However, vessel carried out tank cleaning and gas freeing using HC content of less than 2% by volume instead of 10% LEL during this operation.

• While de-slopping the last tank (typically the Slop (P) tank), the tank was also water-washed in an open cycle by drawing water directly from the sea chest. During this process, the tank residues were continuously discharged ashore via the MARPOL line using the stripper pump. It is recommended that this washing be carried out with (hot water) using the tank cleaning heater to ensure proper Cleaning, adequate drainage, and overall safety. Also, all the solid residues in the tank to be removed completely for undertaking hot work.

• It appears that the tank cleaning procedure was not performed effectively, resulting in the formation of gas pockets within the tank. Though the records indicated that vessel had carried out 03 cycles of washing which were of 45 Minutes duration each, in-adequate isolation of Inert Gas line also contributed towards accumulation of gases in the inert gas pipeline.

• Although a risk assessment for the operation was conducted and signed by the Management team onboard, upon review, it was found to be insufficient for the operations performed, as it did not address the inherent risks associated with the entire operation. Additionally, neither the risk assessment nor the hot work permit approval was obtained from the Company.

• The inquiry indicates that verification and oversight by company was still necessary because the superintendent was on board, and the local agent reportedly applied for the hot work permission to the Port Authorities.

• It was also observed that the (hot work permit) application submitted by the vessel to the Port lacked specific details and was not properly addressed by the Port. The Port issued the hot work permit for an extended duration and without verification of the appropriate conditions, based on the list of works provided by the Master.

• Classification Society (RO) IRS was not informed about the repairs on the vessel by the company.

Read the recommendations: DGS India Casualty Branch Circular 01 2025